| |

Digital Delivery

The first complex, three-dimensional object to be faxed to a remote location is a plastic statuette of Buddha. It was scanned at Stanford University's Computer Graphics Lab. An exact replica is what came out at the other end of the line 400 miles away. Stanford professor Marc Levoy says the ability to scan one side of an object is not very difficult, "These commercially-available laser scanners have been able to do that for a few years. But scanning multiple sides of an object that's complicated and putting them together has been a hard problem. And that's what we've really added."

"The models that we're scanning here are a lot more complicated than anyone else has ever done before," says Mark. "And second of all, it's more automatic than any previous process." The key step is the ability to produce the high-quality, three-dimensional computer models, automating a once laborious process. "When a movie like Jurassic Park is made, they'll typically make models out of plastic or wood. And what they have to do now is break the model into pieces, scan each piece with a laser scanner, and then assemble those pieces by hand in the computer," explains Mark. "It's a very laborious process that takes weeks. We'd like to automate that for them." Once the model is scanned into the computer, it can be faxed to any facility that has the equipment to convert it into a physical object.

To program the laser for a scan this complex, graduate student Brian Curless came up with an algorithm that organizes the information. And what's so unique about this program is that it not only identifies what it sees, but also what it doesn't see. "It gives us everything that was seen, and in addition, we have a method that fills everything that wasn't seen in a reasonable way," says Brian. "And that's important for making a full three-dimensional hard copy of the object." Therefore, if there is a hole, Brian can't duplicate it. Brian's program gives us the computer's best guess as to what's in the place that's missing.

"There's a design firm here in Palo Alto who's made this computer mouse, and the client is in New York," cites Mark. "Well, the client doesn't want to just look at this mouse, they want to feel it. And so we'd like to fax the entire hand-carved prototype to the client in New York who can then say, 'Well, I like this mouse' or 'No, I don't.'" If it's cost efficient, a fax process like this would be a great timesaver for businesses. Mark's dream for this 3-D fax project? He says it depends on how inexpensive it would be, "But at the very least I'd like it to be completely automatic. I'd like to be able to take an object...put it in a box about the size of a microwave oven, shut the door, push a button, and then have a fax appear automatically on the other end." For more information on 3D Systems, call (805) 295-5600

|

Fax imaging has revolutionized the way we conduct business. Within seconds

you can transmit information from your home or office to literally anywhere

in the world. But the next step in facsimile combines laser, photo

chemistry, and software technologies to fax not documents but solid

objects.

Fax imaging has revolutionized the way we conduct business. Within seconds

you can transmit information from your home or office to literally anywhere

in the world. But the next step in facsimile combines laser, photo

chemistry, and software technologies to fax not documents but solid

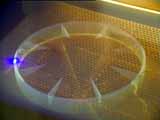

objects. By laser scanning the six-inch statuette, they converted it to a 3-D model.

They transmitted the model electronically to a company called 3D Systems. 3D

Systems uses a process called stereo lithography to create plastic models.

After the ten-hour process, they mailed an identical statue back to the

researchers.

By laser scanning the six-inch statuette, they converted it to a 3-D model.

They transmitted the model electronically to a company called 3D Systems. 3D

Systems uses a process called stereo lithography to create plastic models.

After the ten-hour process, they mailed an identical statue back to the

researchers. "The way the model is actually built up is there's a layer of liquid resin,

which is hardened selectively by a laser," adds Mark. "And then another

thin layer of resin is laid down, and then again hardened by a laser. And so

the whole thing is built up in the layers, and the layers are very thin.

They are a tenth of a millimeter." The Buddha statuette has 300 layers.

"The way the model is actually built up is there's a layer of liquid resin,

which is hardened selectively by a laser," adds Mark. "And then another

thin layer of resin is laid down, and then again hardened by a laser. And so

the whole thing is built up in the layers, and the layers are very thin.

They are a tenth of a millimeter." The Buddha statuette has 300 layers. The ability to quickly image solid objects will no doubt be adopted by

Hollywood. But the fax capability holds the most promise for business and

scientific application.

The ability to quickly image solid objects will no doubt be adopted by

Hollywood. But the fax capability holds the most promise for business and

scientific application.